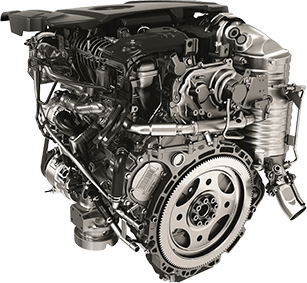

Jaguar just came out with 3.0-litre diesel engine, the inspiring AJ-V6D Gen III, available in a couple of power outputs for its XF S Sedan for the European market. The new V6 Engines is basically a derivative of the 2.7-litre engine gets 12% more fuel average and even produces 10% less CO2 (179 g/km) when compared to the 2.7-litre engine. As far as the power of this bad boy is taken into account, it has increased by 33%. The latest 3.0L engines are Euro 5 compliant.

The 275PS (271 HP, 202KW) carries through 600 Nm of torque and it takes the sedan from rest to 60 mph in just 5.9 seconds while presenting an excellent combined fuel economy of 35mpg (42 mpg, 6.7 L/100km) with 12% more fuel economy compared to the 2.7-litre V6 Diesel Engine. The engine comes up in 240PS (237 hp, 177kw) variant with 16% greater power and 15% more torque than the 2.7-litre diesel engine.

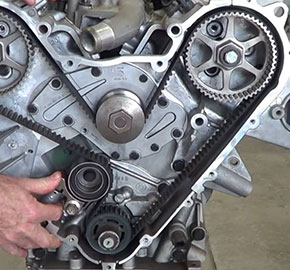

The centrepiece of the new engine is the parallel sequential turbocharger system, the first of which will be fitted to V-engine. It comes up with incredibly high torque throughout the entire engine rev range, improved throttle response and low CO2 emissions. The twin-turbochargers work magnificently to give off 61% more torque from 1,500 rpm than the 2.7L diesel.

For your quotidian driving needs including highway cruising, a turbocharged engine can take care of everything to put up with your expectations within a smaller and fixed-geometry. The secondary turbo is dormant which means saving your precious time and energy back with improved driving efficiency. When the engine reaches at 2,800rpm, the secondary engine comes into play within a short time period of just 300 milliseconds on perceptible turbo-lag or power-step.

There is no denying the fact that valves are the most important part of every engine management system. They segregate the turbocharger both from the exhaust stream and the engine inlet when there’s no need of improving pumping losses.

A few twin-turbo systems depend on a smaller turbo for principle use that mains making use of a larger turbo when higher power is needed. Nevertheless, it’s productive but there’s a disadvantage of higher exhaust pressure and greater pumping loss, says Jaguar. In order to get away with this, the Jaguar system makes use of a larger, variable-geometry turbocharger which is responsible for lower pumping losses and fuel consumption coupled with lesser CO2 emissions.

Jaguar engineers kept their mind on the issue of turbocharger lag specifically at low engine speeds. The new AJ-V6D Gen III 3.0-litre engine makes 500 Nm of torque in just 500 milliseconds of idling. A new common rail fuel injection system produces up to five injections per cycle at a pressure if 2,000 bar. Each injector has got seven holes and the piezo crystals are fitted close to the tip in Jaguar's new injectors which means they are fitted deeper inside the engine in order to dispense quitter operation and sound insulation.

Metering mode is another latest feature of the third-generation fuel-injection system. Conventional diesel common rail fuel pumps excessively provide the injectors with the surplus being carried back to the fuel tank. For the case of metering mode, the pump gives fuel to the injectors only at the rate required. That being so, there will be no increase in fuel temperature and no dissipated energy. The two cylinders (having four valves per cylinder) are made from aluminium and compact graphite iron (CGI) is used in making cylinder block. The greater tensile strength of CGI provides the means for casting a smaller block, some 80mm is shorter than the traditional grey cast iron alternative.

The brand new, water-cooled, exhaust gas circulation system (EGR) is way more effective and drinks up less power than the 2.7-litre unit. The valves which allow exhaust gas into the system are positioned on the hot side of the engine adjacent to the exhaust manifolds. These valves never lose heat while the engine works, so there’s no precipitation of combustion deposits which is common on the engines fitted with cold side valves. Therefore, the EGR system always works at maximal efficiency. As the EGR cooling is so productive, the exhaust gasses can go round the system and carry back to the exhaust pipes, permitting quicker engine warm-up from rest and diminishing emissions still further.

Euro 5 emissions compliance can be got through by making use of traditional diesel oxidation catalyst and diesel particulate filters (DPFs). NOx levels are cut down through the combustion system design, inclusion of a new common rail injection system and the latest EGR system with bypass. Resultantly, specialized NOx exhaust after-treatment is unwanted, evading a possible cost and need to make use of additional expensive metals in the exhaust system. The XF sedan has got the brand new 3.0L engine with a six-speed ZF 6HP28 automatic transmission. Whoa!